How to choose carbide cutting tools

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-12-24 14:36

- Views:

(Summary description)Because the price of carbide cutting tools is relatively high, it is the responsibility of every machining practitioner to use the tools correctly and make the best use of them. How to use carbide cutting tools correctly mainly includes the following aspects:

How to choose carbide cutting tools

(Summary description)Because the price of carbide cutting tools is relatively high, it is the responsibility of every machining practitioner to use the tools correctly and make the best use of them. How to use carbide cutting tools correctly mainly includes the following aspects:

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2021-12-24 14:36

- Views:

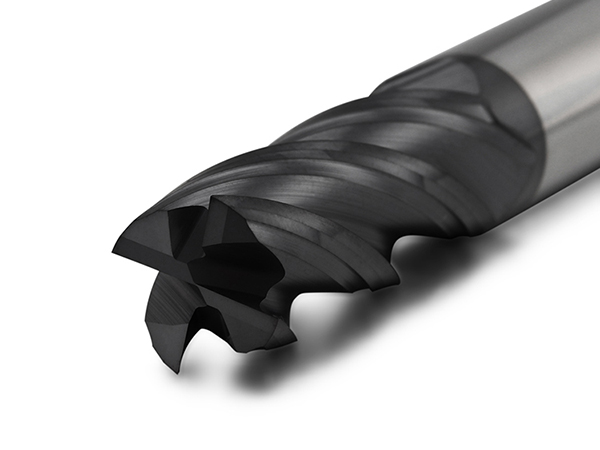

Because the price of carbide cutting tools is relatively high, it is the responsibility of every machining practitioner to use the tools correctly and make the best use of them. How to use carbide cutting tools correctly mainly includes the following aspects:

First, choose the correct machine

Cutting carbide tools can be used in CNC machine tools, machining centers and other machine tools with high power and good rigidity, and the tool tip runout TIR<0.02 should be guaranteed. However, due to the low power and poor spindle accuracy of radial drilling, milling and other machine tools, it is easy to cause early collapse of carbide cutting tools, which should be avoided as much as possible.

Second, choose the correct handle

Spring chucks, side pressure tool holders, hydraulic tool holders, thermal expansion tool holders, etc. can be used, but because the clamping force of the quick-change drill chuck is not enough, it is easy to cause the carbide cutting tools to slip and fail, so they should be avoided.

Third, the correct cooling

1. External cooling carbide cutting tools should pay attention to the combination of cooling directions, form an upper and lower ladder configuration, and reduce the angle between the tool and the tool as much as possible. 2. Internal cooling carbide cutting tools should pay attention to pressure and flow, and should prevent coolant leakage from affecting the cooling effect.

Fourth, the correct milling process

1. When the inclination angle of the drilling surface is >8-10°, it is not allowed to drill. When <8-10°, the feed should be reduced to the normal 1/2-1/3; 2. When the inclination of the drilling surface is >5°, the feed should be reduced to the normal 1/2-1/3; 3 . When drilling cross holes (orthogonal holes or oblique holes), the feed should be reduced to 1/2-1/3 of the normal; 4.2-blade carbide cutting tools should not be reamed.

Scan the QR code to read on your phone

Latest News

How to choose a milling chuck manufacturer

1500142340

monicaduan7

Copyright © 2020 Terek Tool Co.,Ltd. All Rights Reserved

Powered by www.300.cn