The use and classification of cemented carbide inserts

How to use CNC end mills correctly

Factors that should be considered in the selection of cemented carbide milling cutters

Processing characteristics of stainless steel end mills

Influence of the number of teeth of cemented carbide end mills on machining performance

Structural characteristics and requirements of the shank body of carbide end mills

Development of carbide end mil industry

The main points of the use of cemented carbide welding inserts

Model specifications of carbide non-standard tools

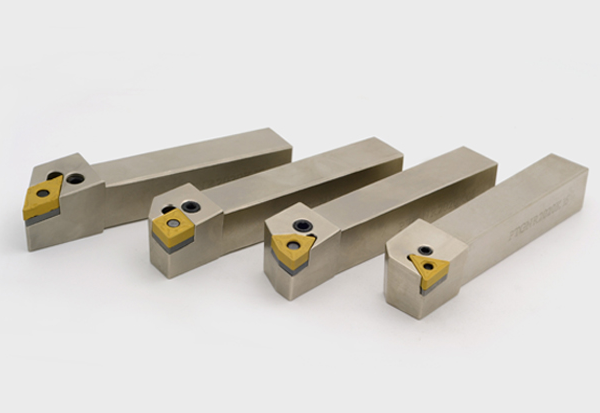

Features of Carbide End Milling Inserts

How to choose the right carbide milling cutter

Analysis of Wear Causes of Cemented Carbide Milling Cutter

language

中国

韩国

韩国

韩国

韩国

韩国

1500142340

monicaduan7

Copyright © 2020 Terek Tool Co.,Ltd. All Rights Reserved

Powered by www.300.cn