How to choose a milling chuck manufacturer

Questions and answers about milling chucks

How to properly maintain the cheap high precision chuck

Precautions for custom high precision chuck from China

What issues should be considered when wholesale high precision chucks

Routine maintenance and maintenance of high precision chuck

How to choose a strong tool holder for holding an end mill

Tips on using alloy milling cutters

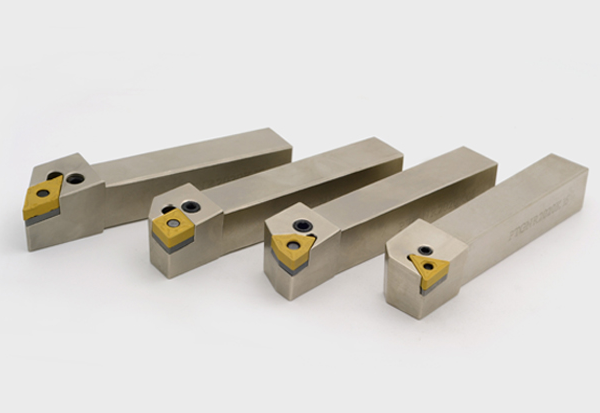

The use and classification of cemented carbide inserts

How to use CNC end mills correctly

Factors that should be considered in the selection of cemented carbide milling cutters

Cause Analysis of Damaged Cemented Carbide Milling Cutter Edge

language

中国

韩国

韩国

韩国

韩国

韩国

1500142340

monicaduan7

Copyright © 2020 Terek Tool Co.,Ltd. All Rights Reserved

Powered by www.300.cn