What are the commonly used high hardness end mills coatings

- Categories:carbide end mills news

- Author:

- Origin:

- Time of issue:2022-05-17 14:41

- Views:

(Summary description)TiN is a general purpose PVD coating that increases high hardness end mills and has a higher oxidation temperature. The coating can be used for high speed steel cutting tools or forming tools to obtain very good machining results.

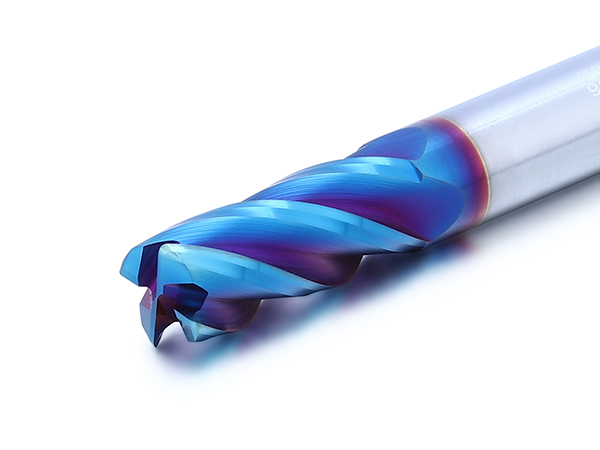

What are the commonly used high hardness end mills coatings

(Summary description)TiN is a general purpose PVD coating that increases high hardness end mills and has a higher oxidation temperature. The coating can be used for high speed steel cutting tools or forming tools to obtain very good machining results.

- Categories:carbide end mills news

- Author:

- Origin:

- Time of issue:2022-05-17 14:41

- Views:

(1) Titanium nitride coating (TiN)

TiN is a general purpose PVD coating that increases high hardness end mills and has a higher oxidation temperature. The coating can be used for high speed steel cutting tools or forming tools to obtain very good machining results.

(2) Titanium nitride carbide coating (TiCN)

The carbon element added in TiCN coating can improve tool hardness and obtain better surface lubricity, which is an ideal coating for high-speed steel tools.

(3) Nitrogen aluminum titanium or nitrogen titanium aluminum coating (TiAlN/AlTiN)

The alumina layer formed in the TiAlN/AlTiN coating can effectively improve the high temperature machining life of the tool. Carbide tools mainly used for dry or semi-dry machining can choose this coating. Depending on the ratio of aluminum and titanium contained in the coating, AlTiN coatings can provide higher surface hardness than TiAlN coatings, making it another viable coating option for high-speed machining.

(4) Chromium nitride coating (CrN)

The good anti-blocking properties of CrN coating make it the preferred coating in machining where built-up edge is prone to occur. After applying this almost invisible coating, the machining performance of high-speed steel or carbide cutting tools and forming tools will be greatly improved.

Scan the QR code to read on your phone

Latest News

How to choose a milling chuck manufacturer

1500142340

monicaduan7

Copyright © 2020 Terek Tool Co.,Ltd. All Rights Reserved

Powered by www.300.cn