Why do high hardness end mills have R angle or C angle design

- Categories:carbide end mills news

- Author:

- Origin:

- Time of issue:2022-08-12 15:32

- Views:

(Summary description)High hardness end mills have r angles, or C angles, which are required by the process. During the machining process, the force surface of the tool tip is relatively small.

Why do high hardness end mills have R angle or C angle design

(Summary description)High hardness end mills have r angles, or C angles, which are required by the process. During the machining process, the force surface of the tool tip is relatively small.

- Categories:carbide end mills news

- Author:

- Origin:

- Time of issue:2022-08-12 15:32

- Views:

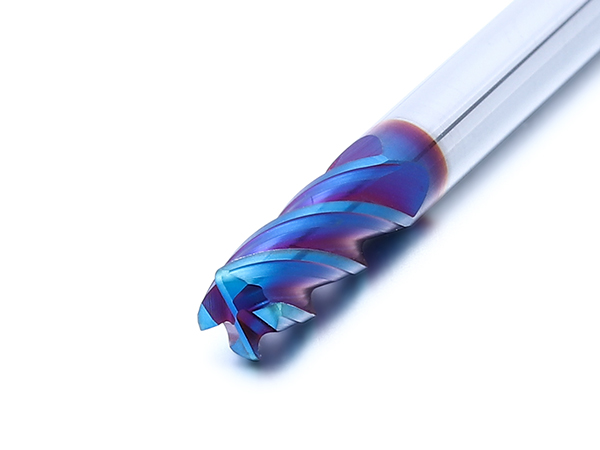

High hardness end mills have r angles, or C angles, which are required by the process. During the machining process, the force surface of the tool tip is relatively small. When machining hard materials or materials with impurities, the tool tip wear or chipping will easily occur. Designing an R angle or a C angle on the tool tip can be done. It has a protective effect on the tool tip, which can effectively prevent the occurrence of this situation, thereby increasing the tool life.

High hardness end mills are rotary cutters with one or more teeth for milling. When working, the cutter teeth cut off the allowance of the workpiece intermittently in turn. Milling cutters are mainly used for machining planes, steps, grooves, forming surfaces and cutting workpieces on milling machines. When optimizing the milling effect, the insert of the milling cutter is another important factor. In any milling, it is an advantage if there are more than one inserts participating in the cutting at the same time, but too many inserts participating in the cutting at the same time is a disadvantage.

Scan the QR code to read on your phone

Latest News

How to choose a milling chuck manufacturer

1500142340

monicaduan7

Copyright © 2020 Terek Tool Co.,Ltd. All Rights Reserved

Powered by www.300.cn